Manufacturing CRM Development Guide: Features, Impact & Estimated Costs

In the maufacturing sector the term which is customer expectations have significantly evolved. Success isn’t just about having top-notch products or efficient production lines anymore. It’s now all about forging meaningful relationships with customers, quickly adapting to market needs, and managing complex operations with precision. The evolution of Customer Relationship Management (CRM) systems has made them more crucial than ever before. Initially designed to assist sales teams, CRM platforms have now evolved into versatile business tools that promote collaboration across departments, improve customer satisfaction, and facilitate informed decision-making.

For manufacturers, CRM is more than just keeping track of sales leads. It’s about uniting teams, making operations more efficient, and having a complete picture of customer interactions from the first sales pitch to after-sales support. CRM helps companies break down barriers between departments like sales, service, and production, while giving instant access to important data. With digital transformation becoming a top priority, a properly implemented CRM system allows manufacturers to offer personalized experiences, forecast demand accurately, and improve operational efficiency.

In this blog, we’ll be delving into how CRM is transforming the manufacturing industry. We’ll cover everything from its effects on efficiency and growth to the key features, best practices for implementation, and common challenges.

The Customer Relationship Management (CRM) process is like the secret sauce that helps companies manage and improve their interactions with customers. In the world of manufacturing, where things can get pretty complicated with long sales cycles and customized products, having a solid CRM process in place is super important.

The CRM process begins with collecting data from various sources such as emails, trade shows, website forms, and marketing campaigns. This data is then analyzed to identify patterns, preferences, and opportunities. The process involves nurturing leads, managing accounts, tracking communications, and providing tailored solutions based on customer behavior and needs. It also includes managing quotes, orders, service requests, and facilitating collaboration between sales, marketing, and service teams.

What sets the CRM process apart for manufacturers is its ability to centralize customer-related operations and provide actionable insights. By leveraging automation, analytics, and integration with other enterprise systems, manufacturers can streamline workflows, reduce manual efforts, and make data-driven decisions. Ultimately, this leads to improved customer satisfaction and enhanced business performance.

The implementation of Customer Relationship Management (CRM) systems in the manufacturing industry is having a profound impact on the way businesses operate. No longer confined to simply tracking sales, modern CRMs serve as a centralized platform for gathering customer intelligence, planning sales strategies, executing marketing campaigns, delivering services, and fostering internal collaboration. In an industry where efficiency and customer satisfaction are paramount to success, CRM facilitates data-driven decision-making and cultivates stronger client relationships.

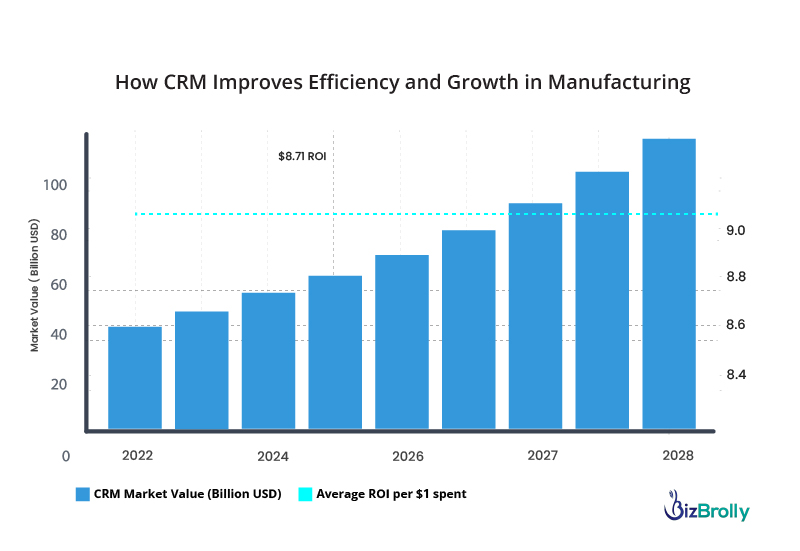

As competition intensifies and customer expectations continue to rise, the adoption of CRM systems is rapidly increasing. According to Grand View Research, the global CRM market was valued at $58.82 billion in 2022, with a projected Compound Annual Growth Rate (CAGR) of 13.9% through 2030. Manufacturers are recognizing the substantial return on investment from implementing CRM platforms, with Nucleus Research reporting an average ROI of $8.71 for every $1 spent.

Here are some ways in which CRM is driving tangible improvements in manufacturing operations:

CRM systems meticulously track every customer interaction, from initial contact to post-sale support. This comprehensive visibility ensures that all team members are well-informed about the customer’s journey, enabling sales and service teams to provide personalized, timely responses and anticipate needs. The outcome is enhanced engagement and the development of stronger, trust-based relationships.

CRM automates repetitive tasks such as data entry, follow-up reminders, lead allocation, and service requests. This automation reduces the burden of manual work, minimizes errors, and saves valuable time. By streamlining internal processes, teams can redirect their focus towards strategic initiatives that fuel growth and innovation.

With shared access to customer data, communication between sales, marketing, customer service, and production becomes seamless. Everyone works from the same source of truth, eliminating silos and miscommunication. This leads to faster decision-making, more aligned campaigns, and a smoother customer experience.

Using CRM data, manufacturers can track buying trends, monitor customer demand, and forecast sales more reliably. This allows for better production planning, optimized inventory levels, and a reduced risk of under- or over-stocking. Ultimately, it contributes to cost efficiency and supply chain agility.

CRM tools store detailed service histories and customer preferences, helping businesses offer faster and more personalized support. Issues can be resolved proactively, and loyalty programs can be tailored for each client. This enhances the customer experience and encourages long-term partnerships.

CRM platforms feature dashboards and custom reports that visualize real-time business metrics. Leadership can easily track performance, measure ROI, and uncover trends or gaps in sales and service. These insights allow manufacturers to act quickly and strategically in a competitive market.

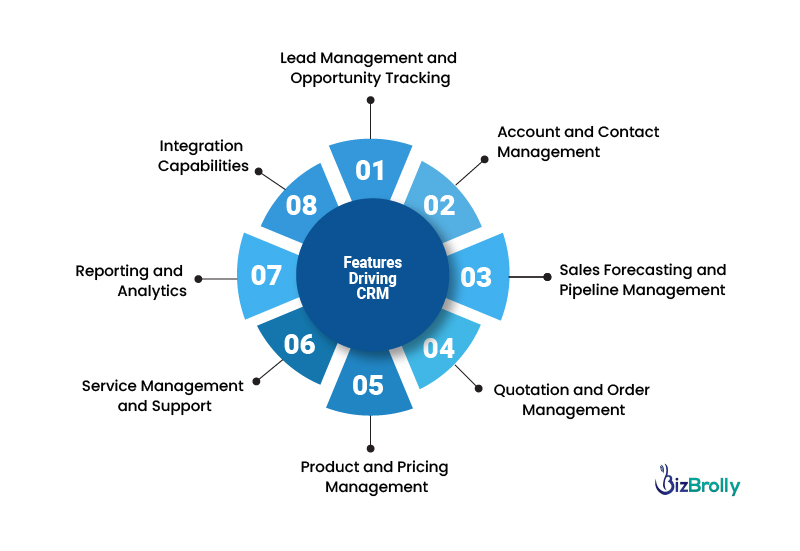

A CRM system tailored for the manufacturing sector goes beyond basic customer tracking. It brings together sales, marketing, production, and customer service under one platform, ensuring that teams operate with clarity, speed, and insight. Below are the core functionalities that make CRM an indispensable tool for modern manufacturers:

Manufacturers often deal with long sales cycles involving complex negotiations and multiple decision-makers. A CRM helps capture leads from diverse sources—like trade shows, websites, and referrals—and organizes them in a centralized pipeline. With automated lead scoring and intelligent routing, sales teams can prioritize high-value prospects and ensure timely follow-ups.

CRM provides a consolidated repository for customer data, including contact details, communication logs, purchase history, and feedback. This 360-degree view ensures that every interaction is personalized and context-rich, improving relationship-building efforts across sales and support functions.

By analyzing historical trends and active opportunities, CRM platforms offer accurate sales forecasts. Pipeline visualization tools give sales leaders a bird’s-eye view of deal progress, helping them identify bottlenecks, reallocate resources, and set more realistic revenue targets.

Quoting and order processes become streamlined with CRM integration. Teams can create and customize quotes, apply pricing rules, and generate order forms—all within the system. This ensures consistency, reduces errors, and accelerates order processing, which is especially vital in fast-paced manufacturing environments.

Manufacturers often deal with a wide array of SKUs, pricing models, and discount structures. A CRM can manage this complexity by storing updated product catalogs and customer-specific pricing, ensuring that sales reps always have access to the right information during negotiations.

Post-sale service is a major differentiator in manufacturing. CRM features like case tracking, service ticketing, warranty management, and self-service portals empower manufacturers to deliver prompt and personalized customer support. It also helps in maintaining long-term client satisfaction and retention.

Customizable dashboards and reports give manufacturers visibility into sales performance, customer engagement, and support metrics. These insights inform strategic decisions, help identify trends, and allow teams to measure the effectiveness of their outreach and customer retention efforts.

A manufacturing CRM must seamlessly integrate with ERP, supply chain, inventory, and marketing systems. This connected ecosystem enables better coordination, reduces data silos, and creates a unified operational framework that enhances cross-functional efficiency and transparency.

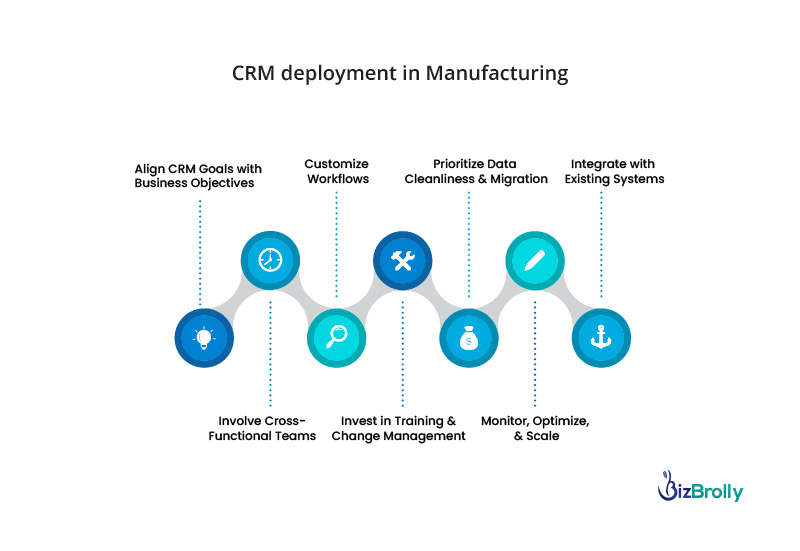

Implementing a CRM system in the manufacturing sector requires a well-planned strategy to ensure adoption, integration, and long-term success. A CRM can be a powerful transformation tool, but only when aligned with the unique workflows and challenges of manufacturing operations. Here are some proven best practices that help maximize the value of CRM deployment in this domain:

Before selecting a CRM, manufacturers should clearly define what they hope to achieve—whether it’s improving sales pipeline visibility, enhancing customer retention, streamlining service processes, or integrating customer feedback into production planning. These goals will guide feature selection and help establish success metrics from the outset.

CRM implementation should not be seen as an IT or sales-only project. Instead, involve representatives from sales, marketing, production, service, and finance during planning and deployment. Their input ensures that the CRM mirrors real-world workflows and supports collaboration across departments.

Out-of-the-box CRM solutions may not meet the intricate needs of a manufacturing business. Customizing workflows, dashboards, and data fields to reflect lead times, quoting structures, service cycles, and distribution models ensures the system adds value where it’s most needed.

One of the biggest barriers to CRM success is user resistance. Provide thorough training to all end-users and create role-specific guides. Regular workshops and onboarding for new hires will increase comfort with the platform. Change management strategies—like appointing internal champions—can further drive adoption.

Migrating data from legacy systems or spreadsheets can be overwhelming. It’s important to clean and validate this data before it’s transferred into the CRM. Inconsistent or outdated records can hamper functionality and reduce user trust in the system’s accuracy.

To create a unified tech stack, the CRM should integrate smoothly with ERP, inventory management, email platforms, and marketing automation tools. This reduces duplication, ensures real-time updates across systems, and provides a holistic view of operations and customer activity.

CRM implementation is not a one-time effort. After going live, manufacturers should regularly evaluate CRM usage, collect user feedback, and track KPIs. Continuous optimization—like adding new automations or refining reports—ensures the system grows with the business and stays aligned with evolving goals.

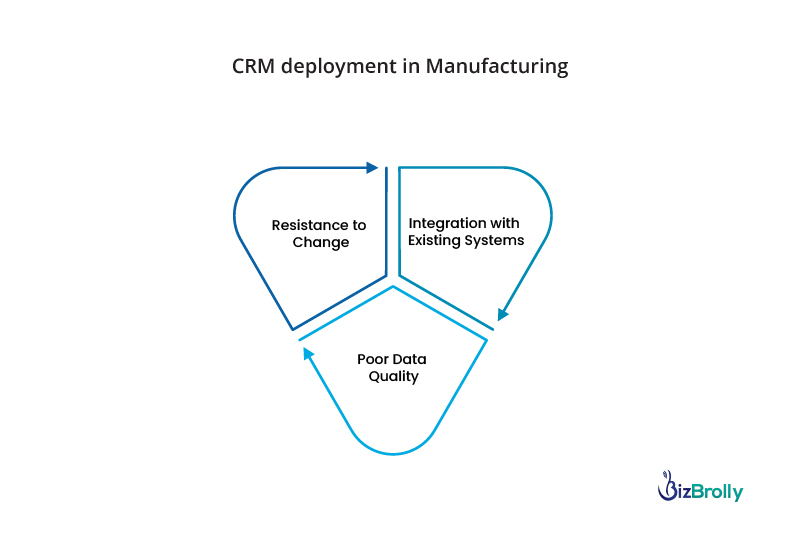

While CRM offers transformative value for manufacturing operations, its implementation isn’t always straightforward. Manufacturers face several hurdles during adoption, but with the right strategies, each challenge can be successfully overcome.

Teams used to legacy systems often resist adopting new tools. This hesitation usually stems from lack of familiarity or fear of technology disrupting their routines.

Conduct hands-on training sessions, involve end-users early in the selection process, and communicate how the CRM will simplify their daily tasks. Leadership support and regular feedback loops further ease transitions.

CRMs must work in harmony with ERP, inventory management, and production software. Integration complexity can delay implementation and impact operations.

Choose a CRM that offers open APIs and pre-built connectors. Work with experienced implementation partners who understand manufacturing systems to ensure seamless and secure data flow.

Dirty, inconsistent, or duplicate data can lead to inaccurate reports, poor segmentation, and lost opportunities.

Begin with a thorough data audit and cleansing process. Establish clear data entry standards and consider ongoing data hygiene practices like automated validation and regular reviews.

Manufacturing businesses today face increasing pressure to deliver not only quality products but also exceptional customer experiences. Achieving this balance requires more than operational efficiency—it calls for integrated systems that foster better relationships, provide actionable insights, and support agile decision-making. CRM plays a pivotal role in helping manufacturers meet these demands.

Far from being just a sales or marketing tool, CRM has become a vital component of the manufacturing ecosystem. It empowers businesses to manage customer interactions, streamline processes, improve demand forecasting, and boost overall productivity. When paired with ERP, supply chain, and service management tools, CRM helps break down departmental silos and encourages a truly connected enterprise.

Implementing a CRM system, however, is not a plug-and-play solution. It requires strategic planning, alignment across departments, and a clear understanding of long-term goals. Challenges such as data migration, employee resistance, or integration with legacy systems must be addressed proactively to ensure success.

At BizBrolly, we specialize in crafting CRM solutions tailored to the unique challenges of the manufacturing sector. From initial setup to seamless integration and user training, our expert team ensures your CRM journey delivers measurable results. Let us help you turn your customer relationships into your biggest competitive advantage.

Partner with BizBrolly to build smarter, stronger, and more scalable manufacturing operations.

The retail sector is continually changing, fueled by evolving consumer demands...

Explore more

Artificial Intelligence (AI) is rapidly evolving, continuously revolutionizing i...

Explore more

D-23, Sector 63, Noida,

UP - 201307

141 Westgate Dr, Edison,

NJ - 08820

4 Black lion court, Mill road, Kent, UK – ME71HL

2207, 2220 Lakeshore Blvd W, Toronto ON- M8V0C1

94A Central Road, Jacanlee, Johannesburg 2194